ILS Automation’s capabilities span the laboratory to the plant floor through process control and management reporting.

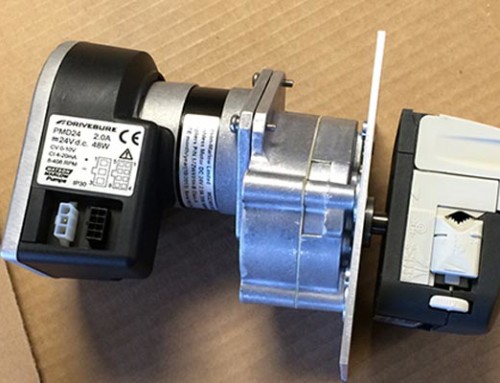

ILS Automation’s integration capabilities span the laboratory to the plant floor through process control and management reporting. Recently, a client asked ILS to design and deliver the automation of a novel liquid delivery system that can charge, clean and feed reactors. For this system, ILS Automation is reading and controlling over 1000 I/O points using a combination of robust field hardware and automation software. This system greatly increases productivity with existing personnel resources.

For another project, ILS Automation installed a modern control, data acquisition and batch reporting system on an existing 1500 liter pilot-scale reactor while folding in existing and new instrumentation. By re-using the existing steel reactor, the customer conserves capital while increasing productivity through improved control and automated PDF-based batch reporting.

If your company is in need of specialized automation, increased productivity, and a greater insight for management, please contact ILS. Automation is our name.