When NBS Eppendorf and B. Braun Sartorius stopped supporting your systems…

You started scanning the used market for boards and parts to keep your equipment up and running.

ILS has a better solution. One that lets you keep your existing glass and stainless vessels and replace the controller with an open, adaptable system for a fraction of the cost of a new system.

The AFC 900 series is a drop-in replacement controller for any glass reactor system, including jacketed reactors, but with direct analog and digital sensor support, scales, MODBUS, and more.

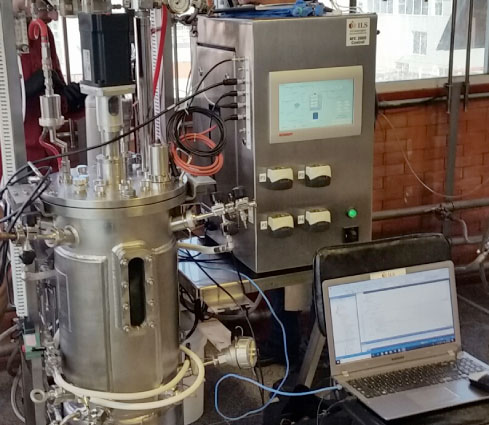

The AFC 2000 series is designed for larger SIP/CIP systems. Let ILS customize your controls with open, non-proprietary, quality components. You decide what to update. ILS will customize the system to meet your current and future requirements for 10% to 20% of the cost of a new system.

The Process

-

1. Assessment

ILS will work with customers to evaluate the current state of the vessel and existing control elements. In some circumstances, ILS can reuse existing control elements such as motor drives, transducers, instruments, valves, etc.

-

2. Design

Customer can choose to replicate the existing capabilities but often upgrades instrumentation, control elements and functionality, if desired. The may include adding a pressure control valve, supporting new instrumentation such optical DO and adding additional gas flow controllers. ILS will work with the customer to design a system, that meets their needs today with room to grow into the future.

-

3. Implementation

ILS will work with the customer and local maintenance/electrical personnel to install the new control system. On-site testing typically involves run-throughs with water and fermentation.

-

4. Support

Typically, new installations require a few runs to “shake-out” the system. This involves monitoring process data and working with operational personnel to discover and remedy any issues. Most often, these issues are programming-related and can be resolved by ILS through remote access to the system.

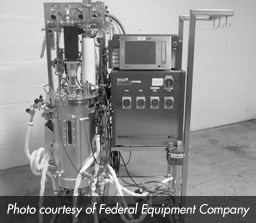

Before & After Controller Replacement

Our Design Principles

- Use open, non-proprietary, readily available, quality components

- Design our equipment to be serviceable by the customer

- Design solutions that are tailored to the customer’s needs

- Customize software & interfaces to match the customer’s requirements

- Provide complete documentation & source code

- Provide ongoing, personal support & technology upgrades for our customers and products