Confidence In A Purpose

ILS helped a biotech startup develop an environmentally-friendly, fully biodegradable plastic straw.

Confidence in a Purpose

The customer in this story is not just another start-up in the biotech world. Already successful from previous ventures, the company founders started this business because they wanted to make a positive impact on the environment. Their goal was to develop a fully biodegradable plastic with the same manufacturing properties as petroleum-based plastics. Originally, one of the target applications was to replace the plastic lining used in paper coffee cups. The lining is nearly invisible, but when you compost paper coffee cups, you will end up with a non-compostable plastic bag. What the founders couldn’t foresee was the recent headlines banning plastic drinking straws along many of the ocean-neighboring states.

Confidence in the Controls

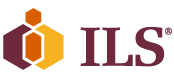

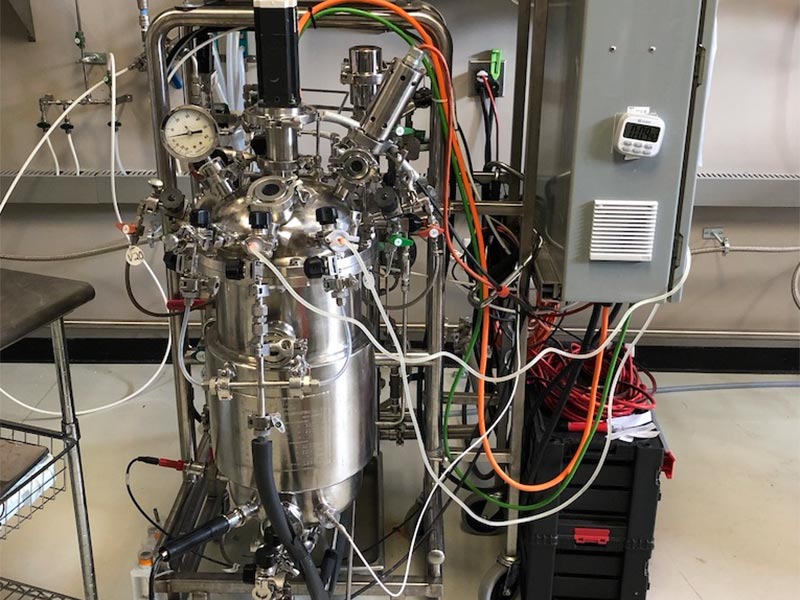

When the company founders approached ILS Automation in 2017, their plan was to purchase used stainless bioreactors at a substantial discount, add all new custom industrial controls, and refurbish the tank mechanically where needed. The first system was a used 30 liter custom manufactured tank. ILS set to work building the PLC-based control panel while company personnel worked on getting the plumbing in order.

Used stainless bioreactor systems, when treated properly, easily outlive their control systems. The benefit of the ILS solution is that the cost of the controls are based on the functionality and not the size of the tank. The controllers for a 30 liter, 300 liter, and 3000 liter system are fundamentally the same and so their costs are similar. Tank size changes the size of some components, motors in particular, but these make a up a small part of the overall project cost. But even at the 30 liter level, retrofit bioreactor controllers are more cost effective than purchasing new bioreactor systems.

Confidence in the Scale Up Process

The 30 liter system was delivered, Batch Expert+ was installed and configured, and the company was already shopping for the next two systems. On the used market, they were able to purchase a set of 250 liter and 1500 liter Sartorius reactors. The plan was the same; new retrofit bioreactor controllers with the same functionality and sensors as the 30 liter system.

Providing identical human interfaces across all systems is a major benefit for users and cuts down on training time. The recipes, alarms, and other features can be shared across all the systems, and Batch Expert+ allows for any number of custom trend charts. In the scale-up process, users can see their current runs with an overlay of historical runs so they can compare growth response as the batch scales up.

Click each image above for more details

250L System

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased. No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

1500L System

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased. No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

3L system

Confidence in the Lab

While the production of larger batches was continuing, there was a need for more vessels in the development lab. The solution was an ILS 927 Dual Benchtop Controller, built with the same user interface and software as the stainless tanks. The company was able to save even more money by utilizing their existing 3 liter jacketed reactors. For the operators, it was the same interface and controls; no learning curve, just tools designed specifically for their needs.

Confidence in ILS Automation as a Partner

The founders of the start-up knew they wanted better control over their equipment and processes and invited ILS to be their partner from the very beginning of the relationship.

When vendors and customers work together as partners, the process is more open. ILS doesn’t just deliver equipment and disappear. We routinely customize our hardware and software solutions for the times when mass-produced products can’t solve our customers’ problems. Working as partners doesn’t cost more money, but it does lead to better solutions, and in the end, a better bottom line.

ILS team members

An existing or used system with a retrofit bioreactor controller typically saves 50-90% vs the cost of a new system.

Savings

Saved approximately $2 million by retrofitting used equipment vs buying new.

Production Increase

Since controls are standardized across all equipment, operators’ familiarity with the tools resulted in improved efficiency and fewer errors.

Positive Impact

Enabled this company to more cost-effectively develop an environmentally-friendly, fully biodegradable plastic straw.

Less Training Time

No need to spend extra time training employees on how to use different systems. Controls are standard across all processes.