Biofuels & Biochemicals

Custom Engineering Behind Biogas, Biochemical, & Biofuel Production for R&D

ILS Automation has the technology and engineering expertise to monitor and control your biogas, biochemical, and biofuel production from lab to pilot scale applications.

Bioreactor Control Equipment

The methods required to produce biofuels (syngas, renewable natural gas (RNG), bioethanol, biodiesel, butanol, etc.) often require complex, multi-step reactions. From the addition of biomass, through the gasification, cooling, and separation processes, the materials being treated must maintain a consistent temperature, proper pressure (if required), and be able to react to the precise addition of gases and chemicals to capture the maximum possible energy output from each batch processed.

For labs working with biofuel production from algae fermentation, ILS’s AFC bioreactor controllers give you complete control over the process, especially during R&D phases. Easily scale up production to a pilot plant with modular control system upgrades built with industrial grade, off-the-shelf components.

Our engineering team can help you customize your bioreactor control system to increase quality, reduce contamination, and maximize yield based on your operating circumstances and specifications.

Our AFC series of bioreactor controllers can help you manage your entire biofuel production process, with built-in support for:

-

- Smart probes and analog probes, including:

- Mettler-Toledo: ISM pH, pCO2, Redox, Optical DO, polarographic DO, analog pH

- Hamilton: Optical DO, VisiFerm pH, Incyte Cell Density

- ABER Biomass monitor

-

- Control up to two reactors from any vendor

- Integrated control of up to 6 MFCs per reactor

- An optional water box that lets you maintain control of jacketed reactors and cooling loops

- Standard configuration includes a 500 W stirrer motor (~0.5HP) that supports 2-15 liter reactors

- Gas flow controllers:

- Alicat & Brooks

- PID loops for temperature, pH and DO set to customer specification

- Automated SIP/CIP cleaning cycles for stainless steel reactors

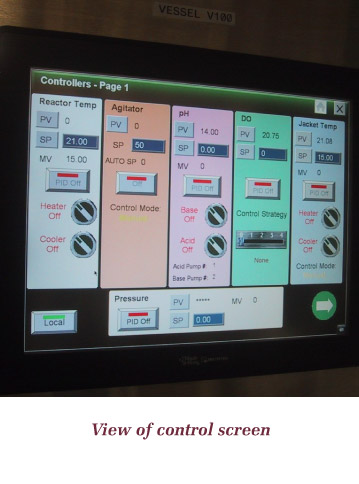

Batch Expert+ Software

Not your typical bioreactor controller software

BE+ integrates all of your existing controllers into a web-based real-time environment that allows both local and remote access to your devices while capturing all of your data into to a SQL Server database.

Customized screens and charts allow our users to learn more from their data, helping them to improve processes and increase yields. The flexibility of the BE+ platform allows users to build as many custom screens as they like.

Unlike other proprietary software packages that make it hard to integrate with multiple vendors’ equipment, ILS does the integration for you. We are famous for our outstanding customer support and won’t leave you with an incomplete solution.

Batch Expert+ features include:

- Recipe management

- Intelligent alarming

- Lockable standardized databases to meet regulatory requirements

- Ability to overlay live data with historical runs in real time

- Ability to pull in data from other on-line & off-line instruments

- Customized trend charts

- A Data Historian that uses open, non-proprietary databases such as Oracle, SQL Server, mySQL, and others. Can easily be managed by IT.