‘Flexible’ Benchtop Controller for Cell Culture Process Development

ILS designs bioreactor platform that supports reactors from 1L to 15L

Project Brief

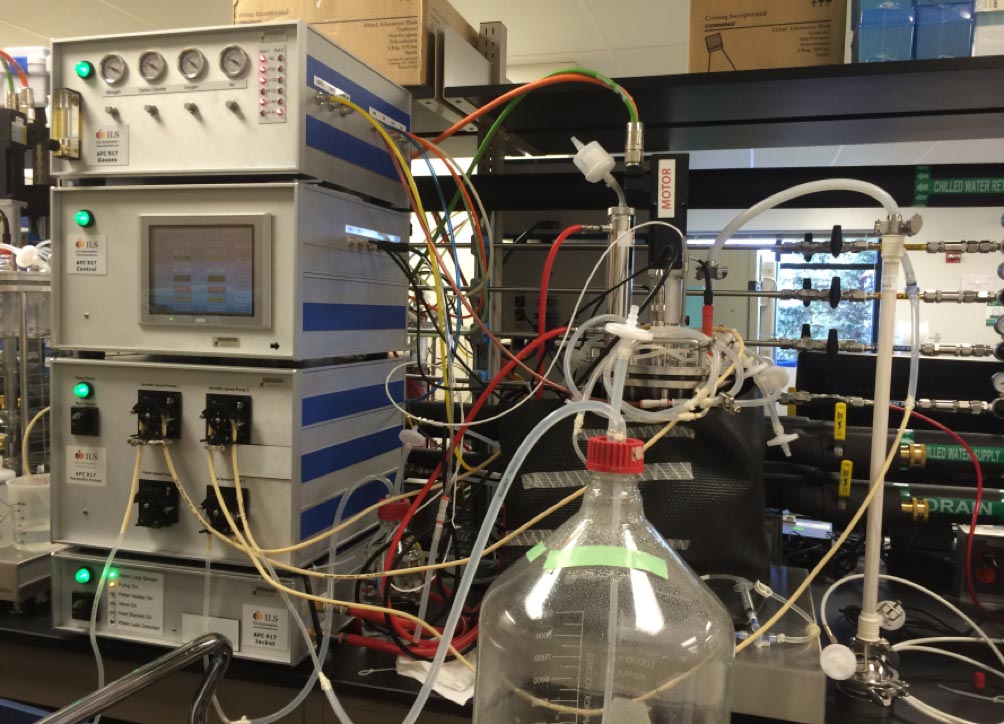

A large biotechnology company required a ‘flexible’ benchtop bioreactor platform that could work with a variety of reactor types, sizes and vendors. ILS provided the AFC 917 benchtop controller that can accommodate blanket or jacketed reactors from 1 liter to 15 liters for cell culture process development.

A separate Gas Box includes 6 Brooks Instrument gas flow controllers. A ‘large’ and ‘small’ Air and O2 allow for accurate control of the various sized reactors. Also included are two manifolds with solenoid valves controlled through the HMI that allow gas mixing between two separate outputs for sparge and/or sparge/overlay.

Digital Sensor Technology

The AFC 917 integrated the latest in digital sensor technology including Mettler-Toledo ISM pH, optical DO and pCO2. The system also includes traditional analog ports pH and DO allowing for a primary and secondary pH and DO probe. Ports for scale weight allow for accurate mass flow control through the included variable speed pumps, mass charging and mass level control.

Bioreactors: Our Specialty

ILS experience with bioreactors has provided our customer accurate and robust control for pH (pump or CO2 cascade), temperature (jacket or blanket), DO (Air, O2, N2, RPM cascade), and pCO2 (CO2, Air, N2 cascade). All controllers include a built-in SP profile.

Open Source Code

The last and most important requirement is that the AFC 917 could change with changing customer requirements and projects. ILS controllers are based upon industrial grade PLCs and HMIs. The source code is open and available. This allows ILS or the customer to continuously improve or update the benchtop controller as requirements change and new sensor technology becomes available.

250L System

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased. No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

1500L System

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased. No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

No sooner than the 30L system was completed and our Batch Expert+ software was installed, the next two retired systems were purchased.

ILS team members on site

A Custom Engineering Solution

Adaptable: Customers can customize a system to meet their needs both now and in the future. Software features are often added to meet the ever-changing needs of cell culture process development or the introduction and integration of new measurement technology.

IoT Approach: We apply the notion of the Internet of Things (IoT) to laboratory automation. The benchtop controller integrates smart control elements and instruments in smart ways. Often this implies a digital interface to read and write actual numbers instead of an analog 4-20 mA approximation. Richer and more accurate/precise data is presented for data analysis and automation. Be it gas flow controllers (Brooks and Alicat), digital probes (Mettler ISM, Hamilton Visiferm), scales (Mettler, Sartorius, ohaus, etc.), cell density (ABER, Fogale), the IoT approach provides smarter solutions.

Open: ILS first-and-foremost provides solutions — not just a piece of equipment that is unpacked from a box. To achieve this goal, we don’t hide behind proprietary equipment or software that is rigid and would conform to our thoughts of what our customers need. Our platforms grow and scale to adapt to customer needs through an open software and hardware system based on industrial grade, off-the-shelf components.

An existing or used system with a replacement benchtop controller typically saves 50-90% vs the cost of a new system.