What We Do

ILS Automation provides customized software & hardware automation solutions. Our amazing support promises to ensure your company’s continued operational success. Increasing your productivity through customization since 2001.

Process Automation Built Around You

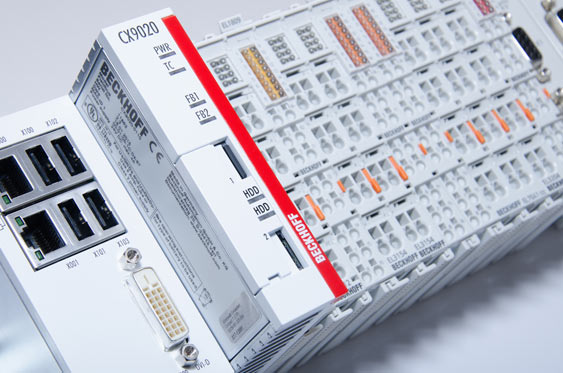

Designing, manufacturing and servicing both the software and hardware in-house has been a huge boon to our customers. It has solidified our standing as experts in process automation and software solutions — experts that pride themselves on the design and realization of custom projects and “out-of-the-box” ideas for our clients, like:

- Integrating unique devices and instrumentation into a cohesive whole and implementing customized control logic

- P&ID review

- HMI screens

ILS’ design engineers work with common hardware protocols that communicate easily with our software. Examples include serial communication like Modbus and other software interfaces such as OPC clients and servers.

The ILS team is proficient in the design and development of process automation and data systems, and the associated software and hardware. Over the last 16 years, we’ve completed a number of successful projects for laboratories and pilot plant automations by employing cutting-edge technologies such as:

By maximizing our ability to meet and exceed our customers’ needs throughout the entire project lifecycle, from preliminary engineering layouts and design to implementation and support, ILS has found success in a very competitive industry. We strive to offer products and services that deliver value and increase productivity for our customers. We take pride in developing successful, long-term relationships.

Ready to leverage our know-how?

How We Add Value Through Automation

We strive to offer services to ensure our products provide productivity and value to our customers. This includes the complete project lifecycle, including design, implementation and support.